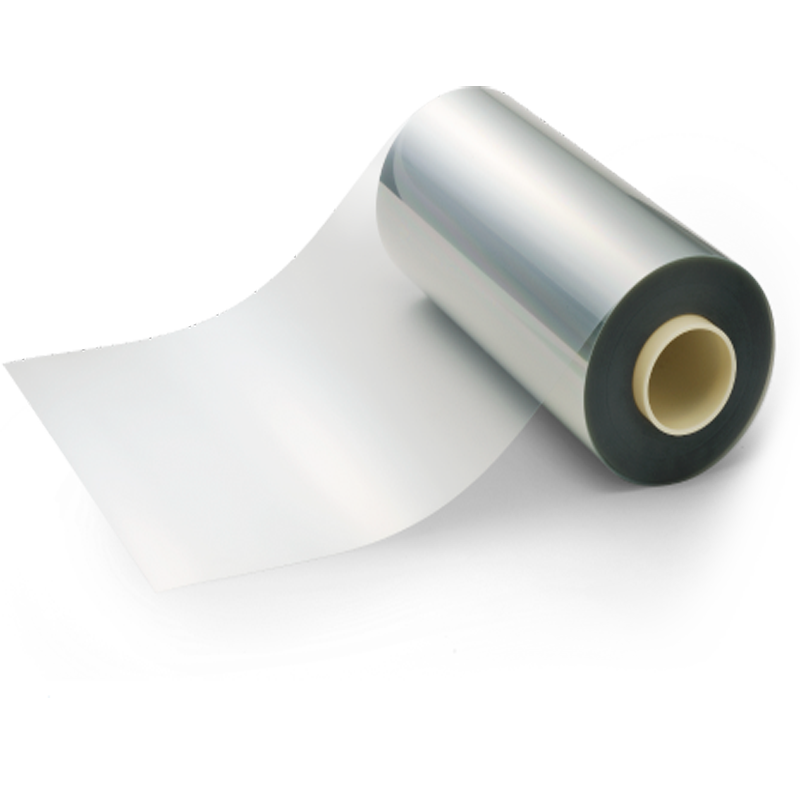

Transparent Rigid PET Sheet Rolls

PET-SHEET.COM

PET-SHEET.COM

- Giới hạn sản xuất:

- Phạm vi độ dày: 0.18mm-1.8mm

- Phạm vi chiều rộng: 350mm-1300mm

- Phạm vi màu: Trong suốt/Trong suốt/Đen/Trắng/Màu tùy chỉnh

- MOQ: 5 tấn (chấp nhận mẫu miễn phí)

- Ứng dụng: Khay ép nhiệt / Khay điện tử / Khay thực phẩm tươi / Đóng gói vỉ

Bạn đang tìm kiếm cái này? Thermoforming PET Sheet Roll. pet-sheet.com is Nhà máy tập trung vào sản xuất và xuất khẩu cứng Thermoforming PET Sheet Roll để định hình nhiệt hoặc đóng gói bọc. về "Transparent Rigid PET Sheet Rolls", Nếu bạn để lại yêu cầu của bạn như độ dày, chiều rộng và ứng dụng của nhựa PET, nhân viên kinh doanh chuyên nghiệp của chúng tôi sẽ báo giá cho bạn mức giá cạnh tranh nhất.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Introduction Of Transparent Rigid PET Sheet Rolls

Transparent rigid PET sheet rolls are widely used in various applications due to their excellent clarity, durability, and chemical resistance.

Key Features

1. Clarity and Gloss: Offers high optical clarity and a glossy surface, making it ideal for packaging and displays.

2. Strength and Durability: Transparent rigid PET sheet rolls Provides excellent impact resistance and rigidity, ensuring structural integrity in packaging.

3. Chemical Resistance: Transparent rigid PET sheet rolls Resistant to many chemicals, making it suitable for various industrial applications.

4. Lightweight: Much lighter than glass, reducing shipping and handling costs.

5. Recyclability: Transparent rigid PET sheet rolls are fully recyclable, contributing to sustainability efforts.

6. Thermoformability: Transparent rigid PET sheet rolls Can be easily thermoformed into different shapes, allowing for diverse applications in packaging and manufacturing.

7. Applications: Commonly used in food packaging, medical devices, electronics, and protective covers.

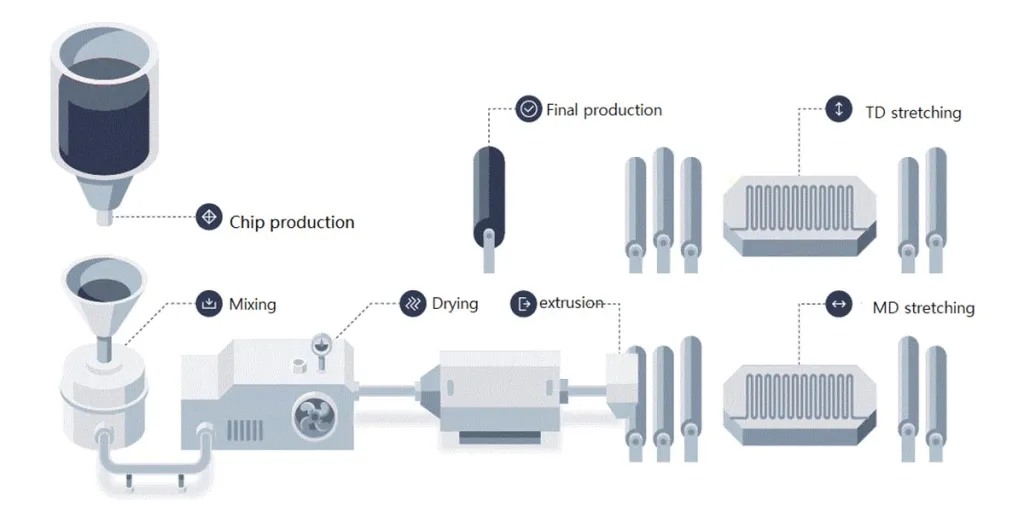

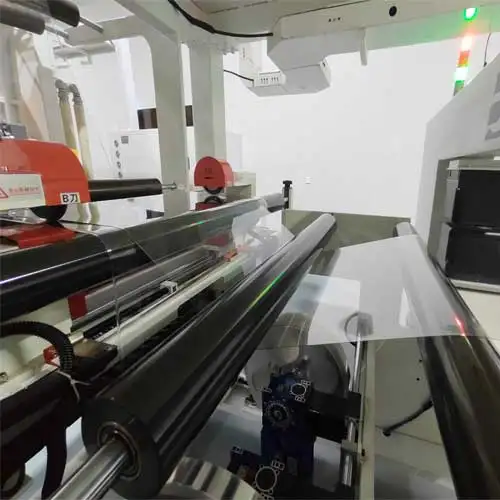

Production Process Transparent Rigid PET Sheet Rolls

Raw Material Preparation: In addition to ensuring the transparency and mechanical properties of PET resin, drying the raw materials is also an important step, as moisture can affect the quality of the film.

Extrusion Molding:

- Mold: It can be more detailed to specify the types of molds, such as flat die or circular die, depending on the product requirements.

Cooling and Solidification:

- Cooling System: It can mention the types of cooling rollers used (such as water-cooled or air-cooled) and how to control the cooling temperature to ensure uniformity of the film.

Thickness Adjustment: It can be added that thickness control relies not only on extrusion speed and cooling speed but also involves adjusting the mold gap.

Quality Inspection: In quality inspection, in addition to transparency, thickness, and mechanical properties, it should also mention checking for surface defects (such as bubbles and scratches).

Packing and Shipping: It can note that final surface treatments (such as anti-static treatment) may be performed before packaging to ensure the safety of the product during transport.

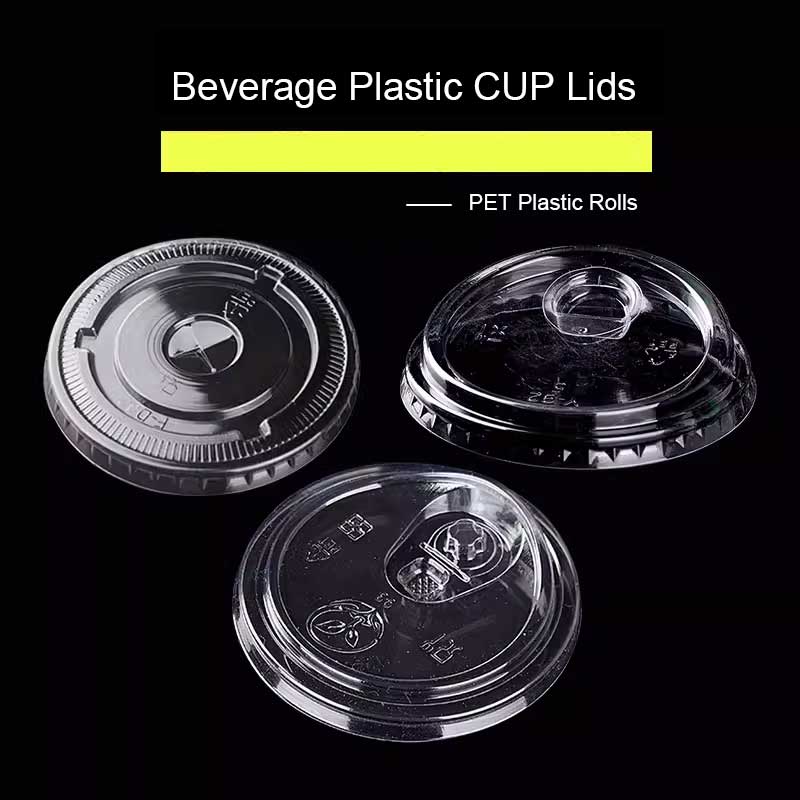

Application of Transparent Rigid PET Sheet Rolls

Transparent rigid PET sheet rolls have a wide range of applications due to their excellent properties. Here are some key applications:

1. Food Packaging: Used for trays, clamshells, and containers that require visibility and protection.

2. Medical Devices: Packaging for pharmaceuticals, surgical instruments, and disposable medical products.

3. Electronics: Protective covers and packaging for electronic components, ensuring visibility and safety.

4. Cosmetics: Packaging for skincare products, perfumes, and cosmetics that benefit from attractive presentation.

Types of Transparent Rigid PET Sheet Rolls

1. Standard Transparent PET Sheet Rolls: Offers good transparency and gloss, suitable for general packaging and display.

2. High Transparency PET Sheet Rolls: Provides higher optical clarity, ideal for applications requiring extreme transparency, such as premium packaging.

3. Food-Grade PET Sheet Rolls: Complies with food safety standards, specifically designed for food packaging to ensure safety and hygiene.

4. Anti-Static PET Sheet Rolls: Treated to reduce static electricity, suitable for packaging electronic components and devices.

5. UV-Resistant PET Sheet Rolls: Features UV resistance, suitable for outdoor applications or packaging for light-sensitive products.

6. Matte PET Sheet Rolls: Surface-treated to reduce glare, suitable for specific printing or decorative needs.

7. Aluminized PET Sheet Rolls: Coated with a layer of aluminum on the surface, enhancing barrier properties and gloss, suitable for protective packaging.

8. Thermoformable PET Sheet Rolls: Specifically designed for thermoforming processes, suitable for creating complex shapes of containers and packaging.

These types of PET Sheet Rolls can meet the specific needs of various fields and industries. If you are interested in a particular type of film or need more information, feel free to let me know!

Tại sao nên chọn pet-sheet.com

Sản xuất đồng đùn

Sản xuất đồng đùn

Kiểm tra chất lượng

Kiểm tra chất lượng

Đóng gói an toàn

Đóng gói an toàn

Chuyển hàng đúng giờ

Chuyển hàng đúng giờ

LIÊN HỆ PET-SHEET.COM

Nhân viên kinh doanh và kỹ thuật viên chuyên nghiệp của chúng tôi sẽ xác định các đặc tính cuối cùng của sản phẩm và giải pháp vật liệu cho ứng dụng cụ thể của khách hàng và sẽ cung cấp cho khách hàng báo giá và lịch trình chi tiết. Vui lòng điền vào mẫu để liên hệ với đội ngũ kinh doanh chuyên nghiệp của chúng tôi.- Thể loại

- Cuộn tấm PET chống tĩnh điện ESD

- Cuộn Tấm PET Nhiệt Định Hình

- Tấm nhựa APET cuộn

- Tấm nhựa cuộn GAG

- Tấm nhựa cuộn PETG

- Tấm nhựa cuộn RPET

- Similar Products No related posts found.

PET-SHEET.COM

PET-SHEET.COM